TOP MIND

CUSTOMIZE CPMPACT ELETRIC PRESS BRAKE

TOP MIND

Customized Small CNC Bending Machine

Professional manufacture R&D of sheet metal machine tools

Delicacy Management ,Preferential Quality, Details Of The Best Perfect Service

The small hydraulic CNC bending machine has a unique design, and the hydraulic system ensures the speed and stability of the downward movement of the upper beam driven by the double cylinder. The machine has a wide range of uses, not only for the production of small and thin workpieces, but also for the production of medium and thick plate workpieces. Compact and modern design with sheet metal curved construction with backstop and stainless steel front tray for increased bending speed and stability. Small footprint and flexible production

Compact & Attractive Design

Low Investment Cost

Energy Saving & Low Noise

Double Cylinder Machine Structure

Standard Equipment

- New Generation DELEM DA53T with 2D Touch Screen Programming

- Germany BOSCH-REXROTH Hydraulic System

- Whole System ESTUN Servo Motor&Drive

- American (HYTEK) Sunny Oil Pump

- Spanish FAGOR Grating Ruler

- Taiwan Ball Screw& Linear Guide

- Backgauge Positioning System

- Electric Motorized Crowning

- Electrical cabinet with Schneider, Siemens components

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

Integral steel welded structure, vibration eliminate stress, high mechanical strength, good rigidity. Hydraulic upward transmission.The frame is processed by CNC floor boring and milling machine to ensure the parallelism and perpendicularity of each mounting surface.

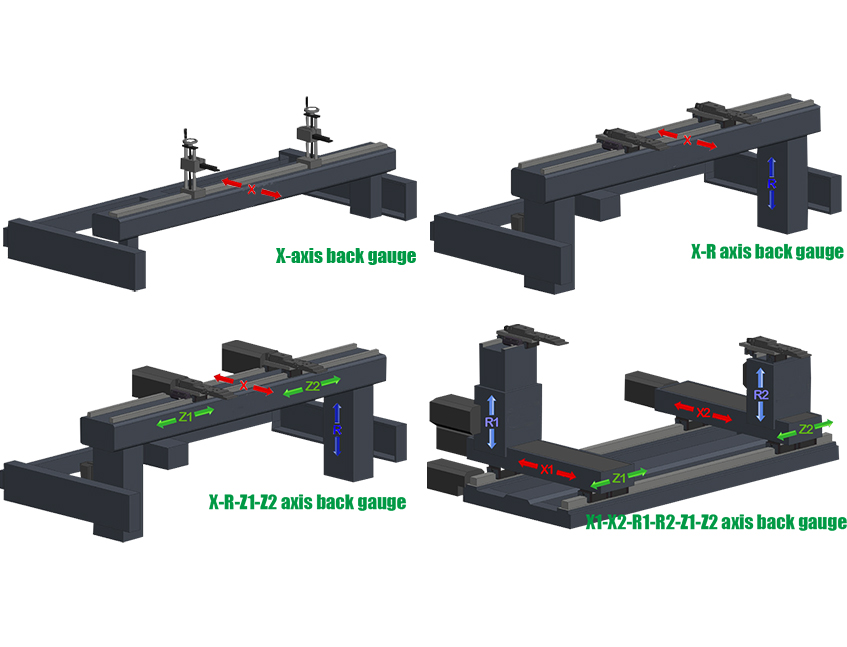

Backgauge Control System

The correct back gauge for the application can have a substantial positive influence on production part volume and accuracy. The more intricate the parts, typically the more axes on the back gaugeyou should have. Volume of parts needs to be considered also. A smart, experienced brake press operator can bend, form and produce some very intricate parts without even a single axis back gauge. However, the more time it takes to form the correct part, the more costs you have in the part. So the best scenario would be to have an experienced operator with the correct back gauge system that will magnify their skills. But in today's market, smart, experienced Press Brake operators are getting hard to find. So the correct back gauge for the application will decrease costs per part by helping to make a good press operator, a great one.

DELEM CNC Control System

DELEM DA53T Touch CNC System

- 10.1" high resolution colour TFT

- “Hot-key” touch navigation

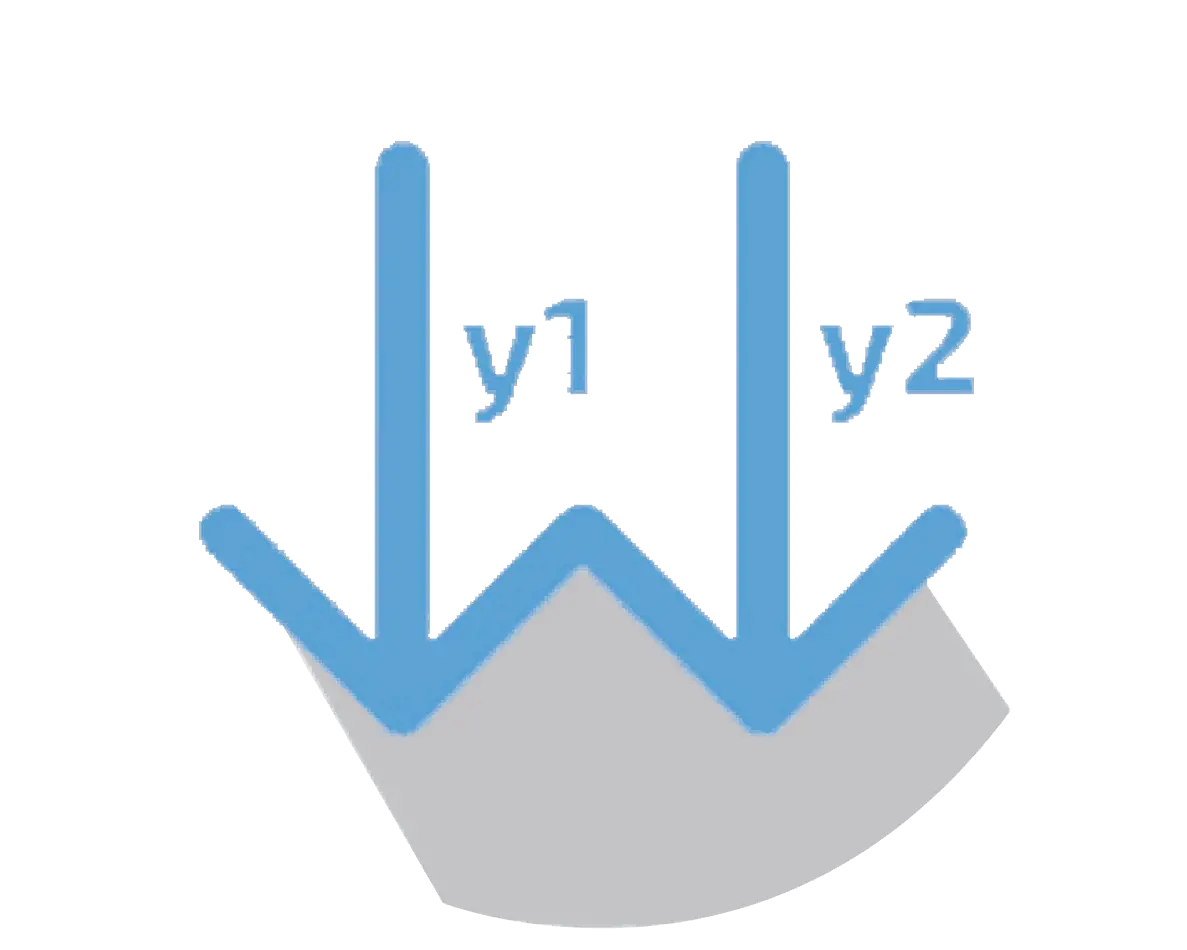

- Up to 4 Axis (Y1,Y2 + 2 aux. Axis)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

Hybrid Electric System

In the simple electro/hydraulic drive system the ram movement is powered by AC servo motors driving hydraulic oil in line with a variable speed pump. This new technology provides:

- Noise Level Reduction 76dba to 63dba

- Increased Ram Speeds (up to 472 IPM)

- 60% Reduced Oil Requirements

- Five Times Better Y1, Y2 Synchronization at High Speed

- Better Accuracy

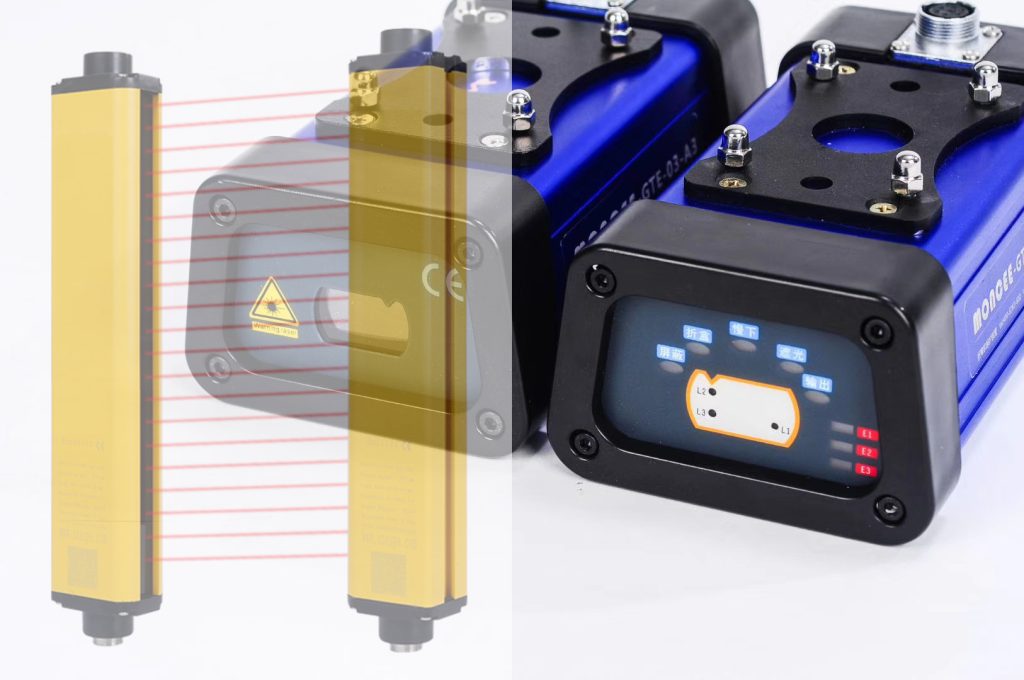

Optical Components

Rear Light Curtain/Laser Protection

The front/rear light curtain has great protection for the operator's fingers from injury caused by misoperation.

Does not affect the efficiency of bending work, can completely solve the safety problem, fully meet the world safety standards.