Your Global Partner for Metalworking Solutions

Through highly competitive cost performance, consistent quality control and world-class service, create unlimited possibilities for your metal processing projects.

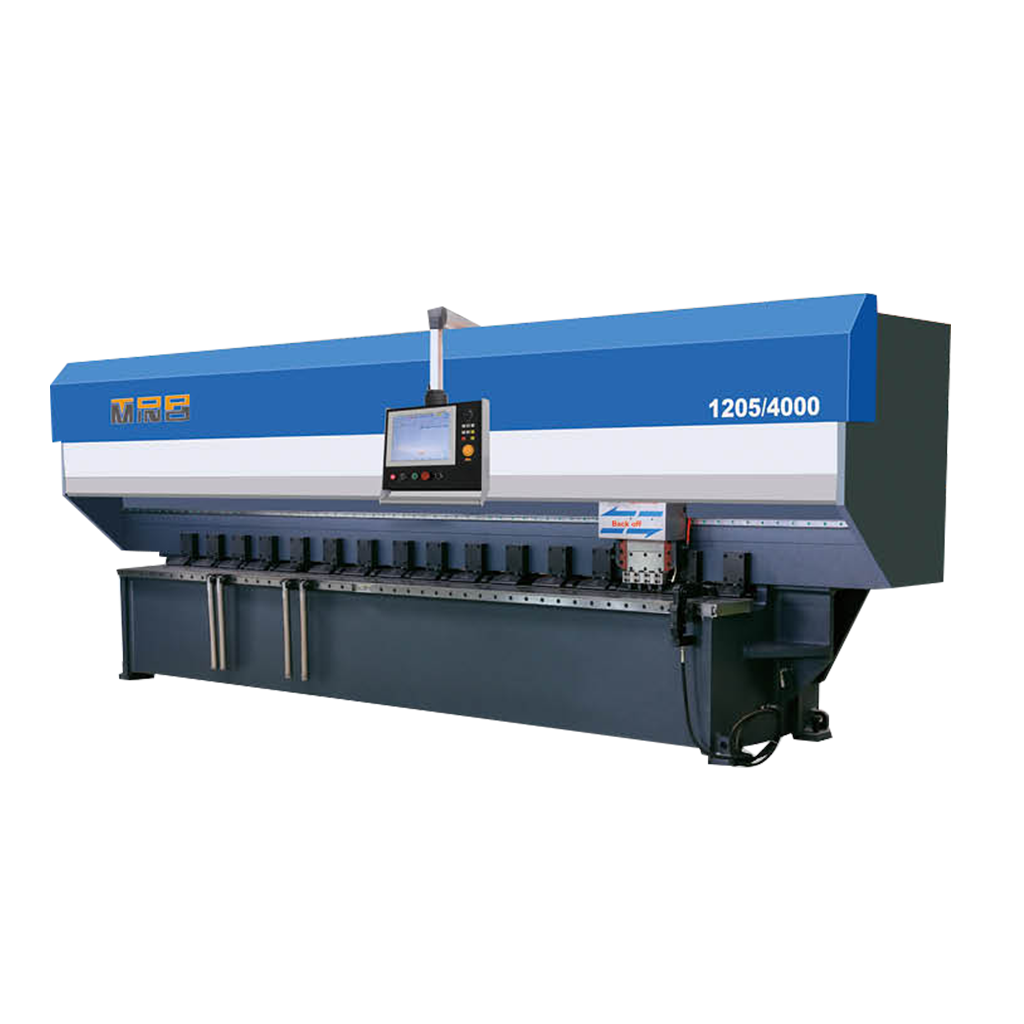

CNC Press Brake

NC Press Brake

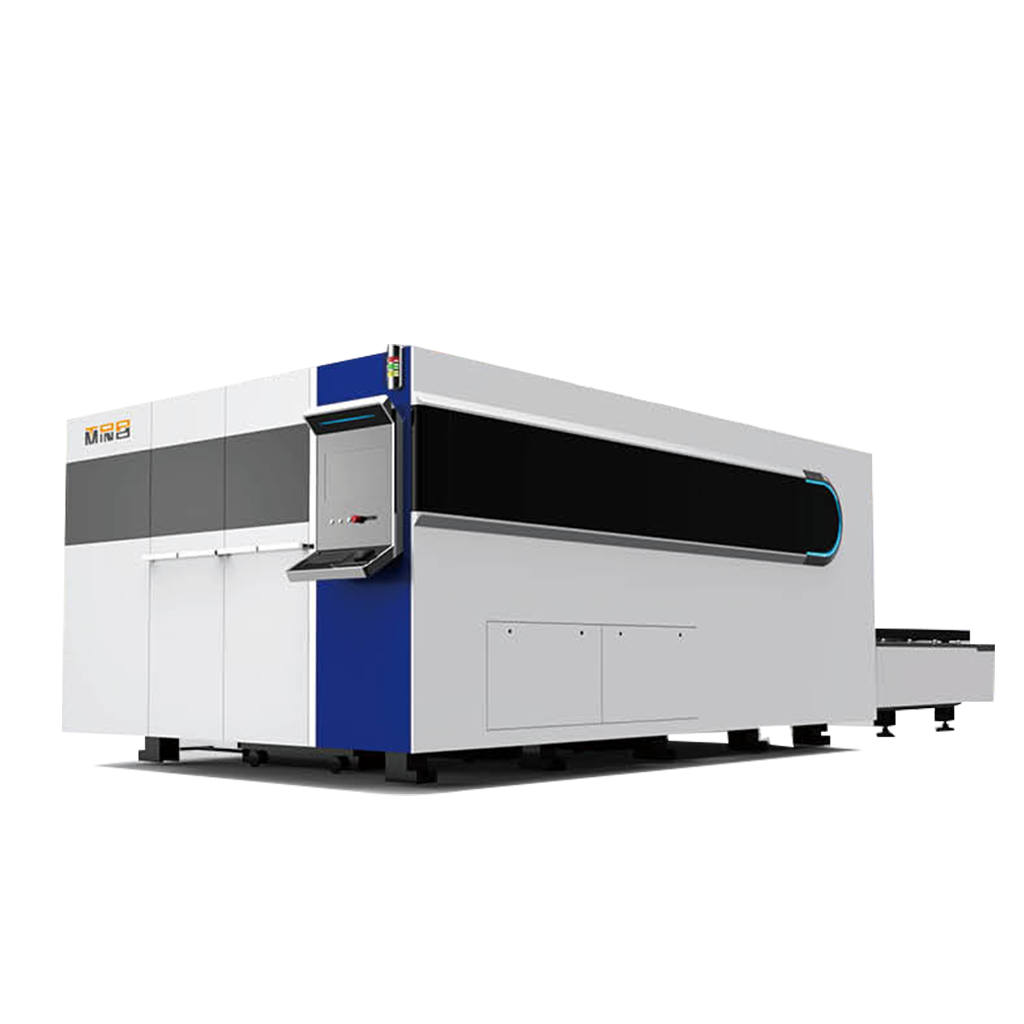

Laser Cutting Machine

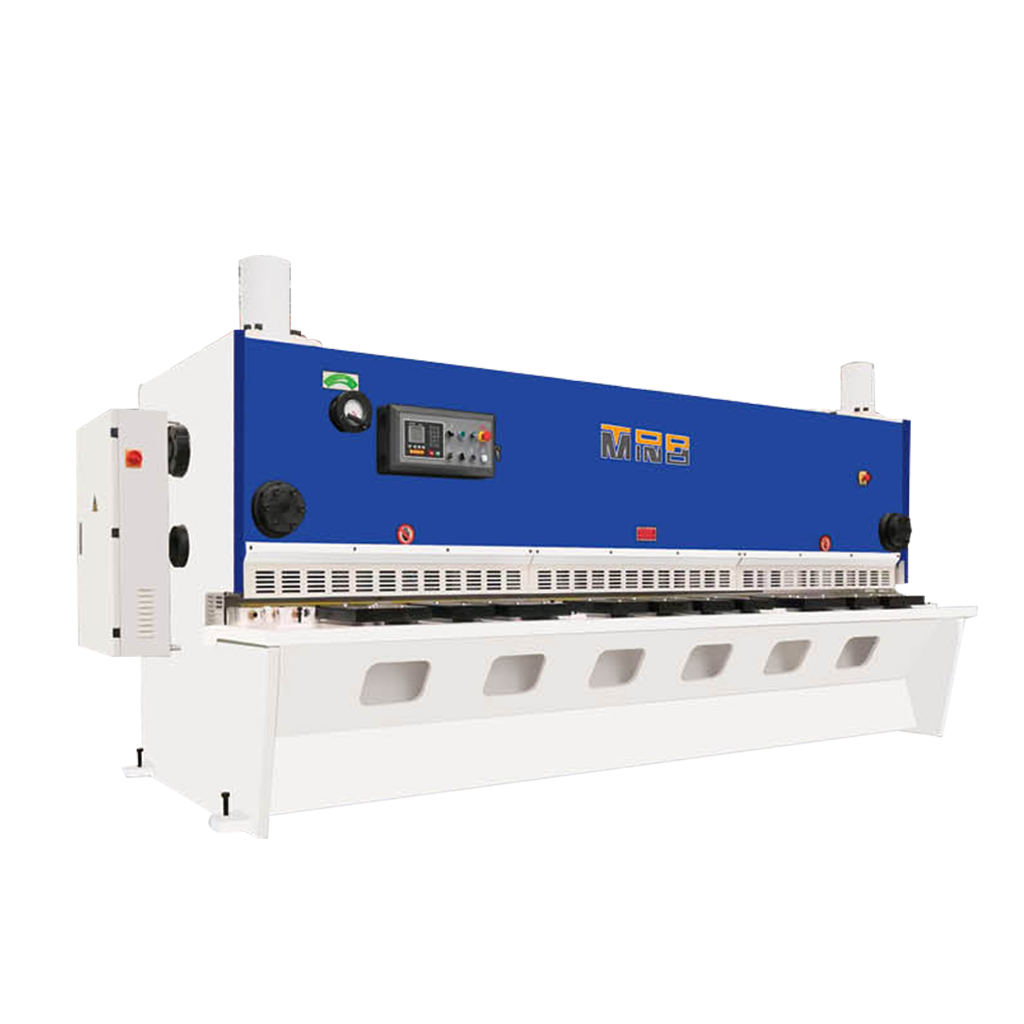

Shearing Machine

V Grooving Machine

Choose And Configure Your Press Brake

Top Mind is a professional intergrated company dedicated to research & development, Production and sales sheet metal equipment. Top Mind Technology Limited, as the headquarter of company, located in Victoria Harbour Centre, HungHom, Hongkong, China, with a long history of production and management, the company adheres to the advanced design concepts, combines the user actual operation demands and the experience, manufactures the reasonable structure and high quality sheet metal processing equipment, insisted on let press brake and services throughout the world.

Top Mind®implements the fine management, pays attention to the quality and details, and improve our service continuously. Our products has passed the European CE safety certification and are exported to many countries and regions in the Europen Union and the world. ISO9001 quality management system is implemented to standard the internal management process and ensure the steady development of enterprises. We have established anintellectual property protection mechanism to encourage innovation and obtain a number of patents to lay a solid foundation for the company's future development.

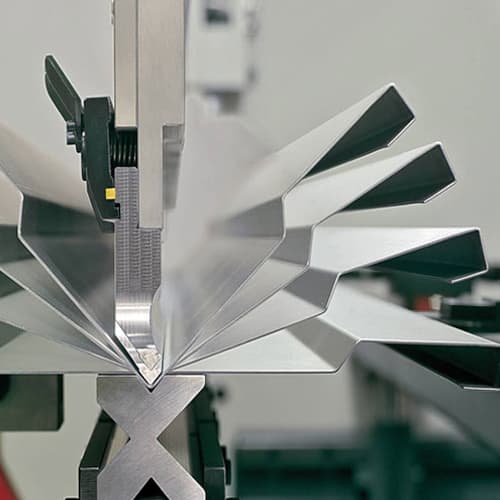

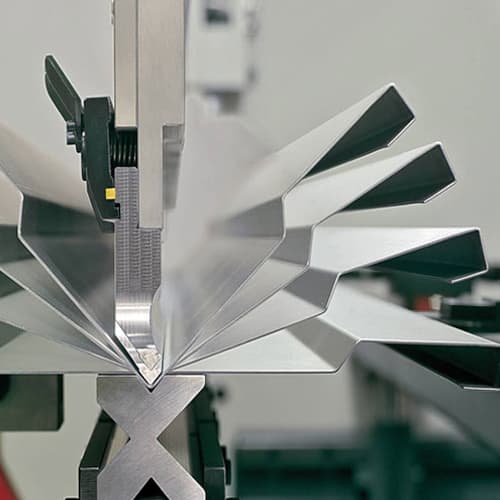

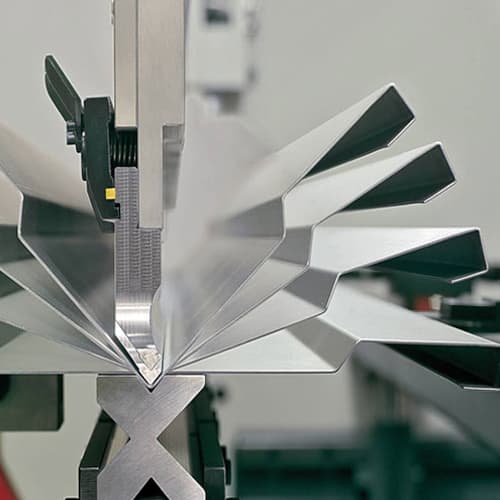

Precision of Top Mind Press Brake

- Overall welded and processed structure.

- Closed loop control mode composed of electric-hydraulic servo valve and measure ruler, ensure the highest precision, bending accuracy and repositioning accuracy are also reach the highest level.

- Integrated hydraulic system decreases the pipe connections, oil leakage and increase the stability and overall reasonable.

- Hydraulic compensation mechanism helps to prevent the deformed slider from affecting the quality of the workpiece and compensation mechanism adjusted automatically by the CNC controller which is convenient and accuracy.

- Controller system adopt Holland Delem, Italy ESA, and Swiss CYBELEC with multi-language selection.

- Back gauge mechanism can control several axis.

Like Us On Youtube

Visit our Youtube page for latest news, updates and stay

connected with us on Facebook.

Choose Your Needs

Press Brake

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Laser Cutting Machine

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

V Grooving Machine

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Shearing machine

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Press Brake

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Trained and qualified technical support team

Our technical assistance service team has extensive experience. They are skilled and trained to handle the technical problem of our clients' machinery,in the shortest time possible,and with the best guarantee.

Online

Teamviewer

Language

English

50/15

Availability

All building sub-units like hydraulic system,CNC systems,program software,operating equipment,etc. are supplied by world-class quality manufacturers from Europe and/or are manufactured and developed by Top Mind.

why work with us

This is a title

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

This is a title

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

This is a title

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

This is a title

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

This is a title

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

This is a title

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Performance Improvement

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Performance Improvement

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard

Performance Improvement

While a place for traditional press technologies will always exist in this new age, servo technologies are starting to become more of a necessity for certain stamping manufacturing operations. Both the standard