TOP MIND

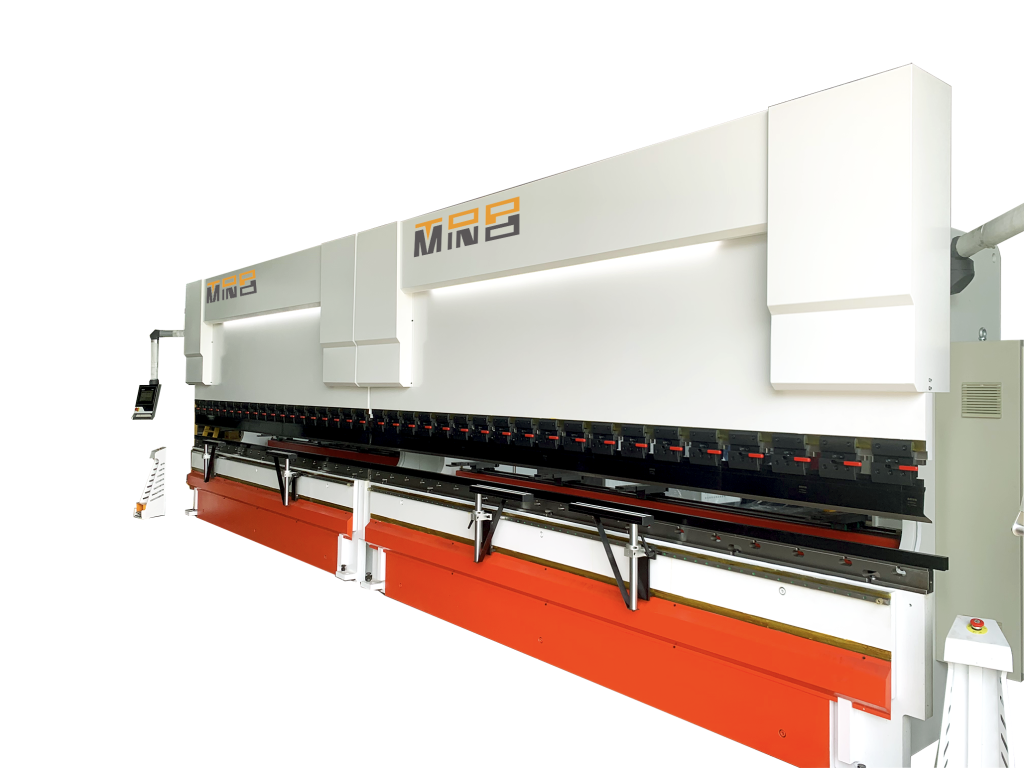

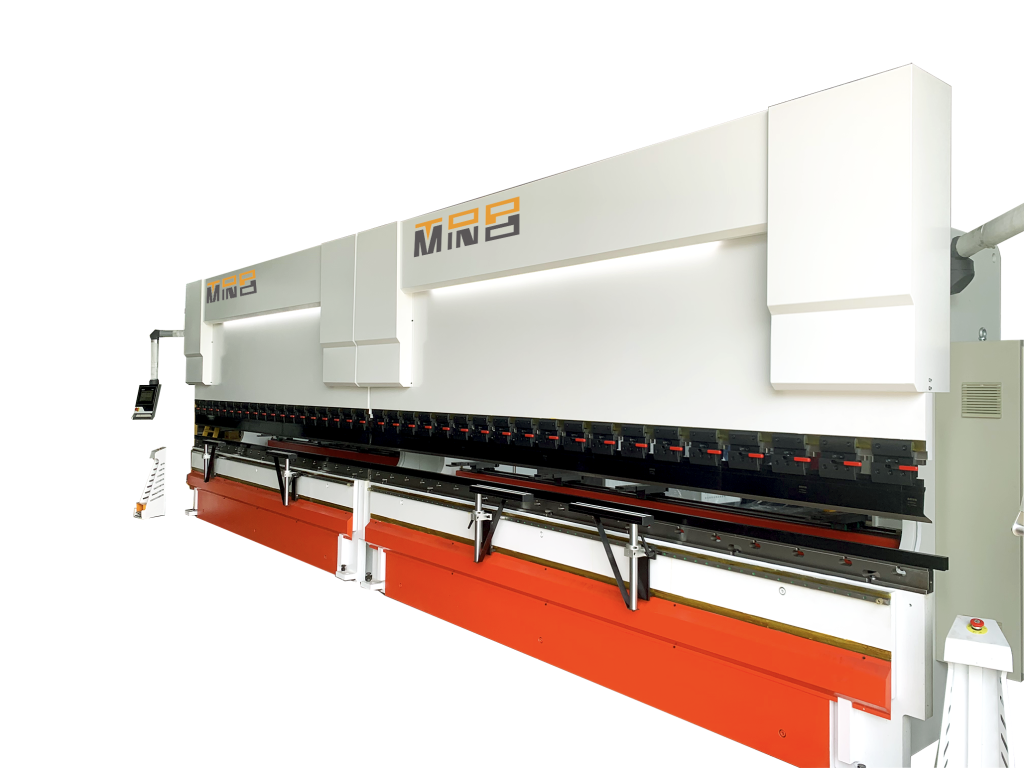

Tandem Press Brake For Sheet Bending

Top Mind

Tandem Press Brake

Synchronous linkage professional bending solutions

Delicacy Management ,Preferential Quality, Details Of The Best Perfect Service

The tandem press brake can provide flexible working capacity. It is usually used for bending longer workpieces. It can not only work separately, but also be used independently, which is more flexible.

Preferential Quality, Low Maintenance

High Efficiency

Linkage and synchronization between two systems

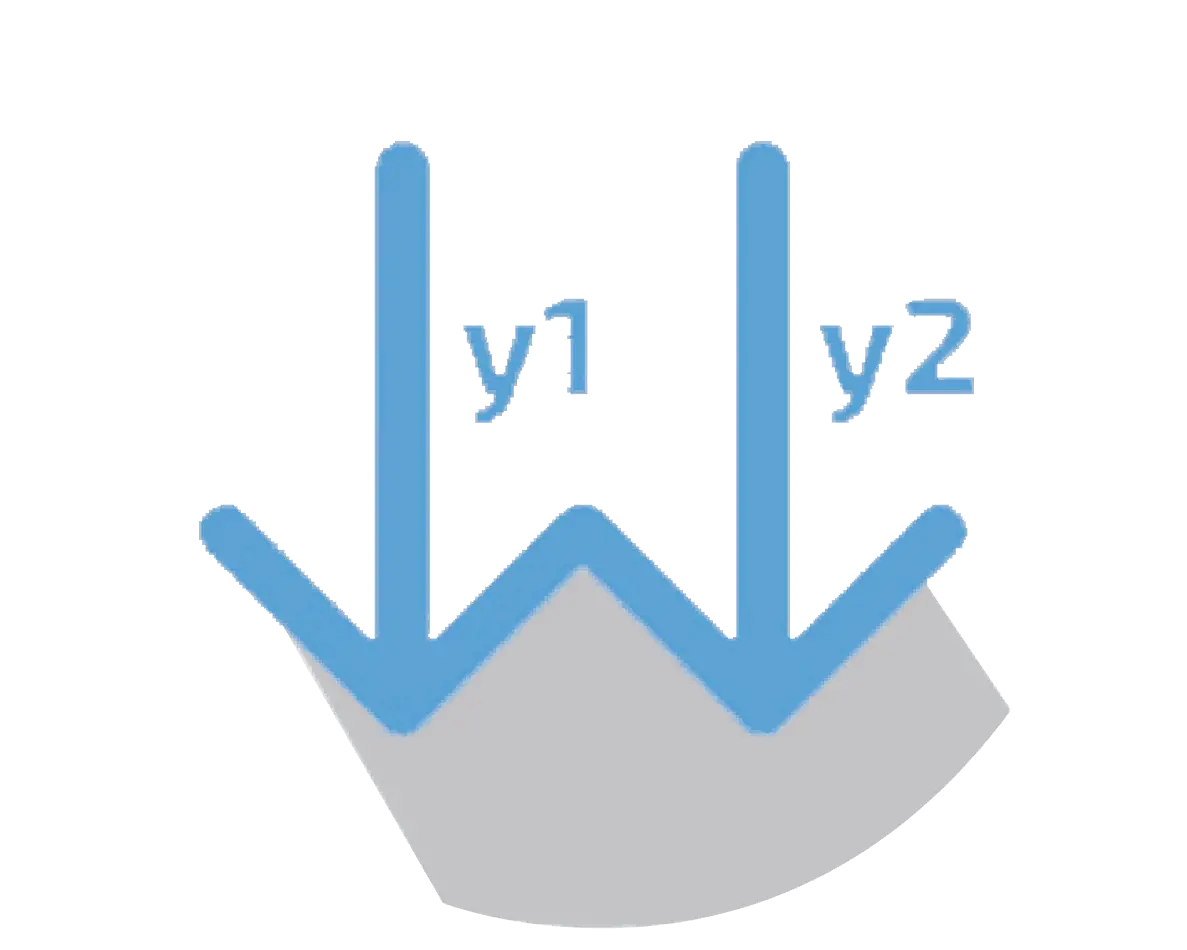

Standard 4+1 Axis, Y1Y2 Independent Control Flexibility

Standard Equipment

- New Generation DELEM DA53T with 2D Touch Screen Programming

- Germany BOSCH-REXROTH Hydraulic System

- Whole System ESTUN Servo Motor&Drive

- American (HYTEK) Sunny Oil Pump

- Spanish FAGOR Grating Ruler

- France Schneider Electric System

- Backgauge Positioning System

- Taiwan Ball Screw& Linear Guide

- Electric Motorized Crowning

- Adjustable Front Support With Linear Guide

- X,Y1,Y2,R+V Axis

Main Structural Performance

Features

The CNC synchronised tandem press brake consists of two bending machines, which are synchronised in a double operation. The machines can work together or independently; the front and rear pushing devices are designed for large workpieces, reducing labour intensity and improving work efficiency. The machine consists of a table slider and left and right plates. Two cylinders are mounted on the left and right side of the machine. The hydraulic system drives the ram downwards under the action of the electrical operating system. The ram is equipped with an upper die, which, when in contact with the workpiece, exerts pressure to shape the workpiece.

CNC Control System

We offer a full range of Delem, ESA and Cybelec control systems, imported from the Netherlands, Italy and Switzerland respectively, in strategic cooperation with suppliers. Reduce the humanized design of the set work steps, especially batch processing, greatly improve the work efficiency.

Hydraulic System

- Adopting integrated intelligent hydraulic system

- Simplified oil connection,

- The system actively synchronizes

- With high anti-bias load ability

- Hydraulic synchronization minimizes wear during normal operation

Double ESTUN Main Servo Motor

Servo motor with low energy consumption, high precision and improved machine production efficiency to make customers more house. Compared with the traditional motor, it can save up to 50% energy consumption, bringing customers the advantages of high efficiency and low operating cost. Dual motor realization pressure is more robust to ensure working accuracy and straightness.

Backgauge System

The correct back gauge for the application can have a substantial positive influence on production part volume and accuracy. The more intricate the parts, typically the more axes on the back gaugeyou should have. Volume of parts needs to be considered also. A smart, experienced brake press operator can bend, form and produce some very intricate parts without even a single axis back gauge. However, the more time it takes to form the correct part, the more costs you have in the part. So the best scenario would be to have an experienced operator with the correct back gauge system that will magnify their skills. But in today's market, smart, experienced Press Brake operators are getting hard to find. So the correct back gauge for the application will decrease costs per part by helping to make a good press operator, a great one.

Crowning System & Press Brake Tooling

The mechanical compensation automatically calculates the compensation value according to the feedback of the system and the grating ruler and the total deformation amount of the table, so that the deformation curve of the bed and the compensation curve are perfectly fitted to ensure the accurate consistency of the straightness and Angle of bending

- Section die 835mm

- One to one design

- Own tooling factory, lower cost

- Uniform completion of heat treatment of higher service life

Fast Clamp

Fast replacement of the upper die, convenient disassembly and assembly to save time and make the work more convenient

Ball Screw & Guide

Taiwan Ball screw and linear guide rail are adopted to ensure the smooth operation of the machine and guranteed the accuracy and speed