Safety Arrangements

LAZER SAFE - PERFORMANCE WITHOUT COMPROMISE

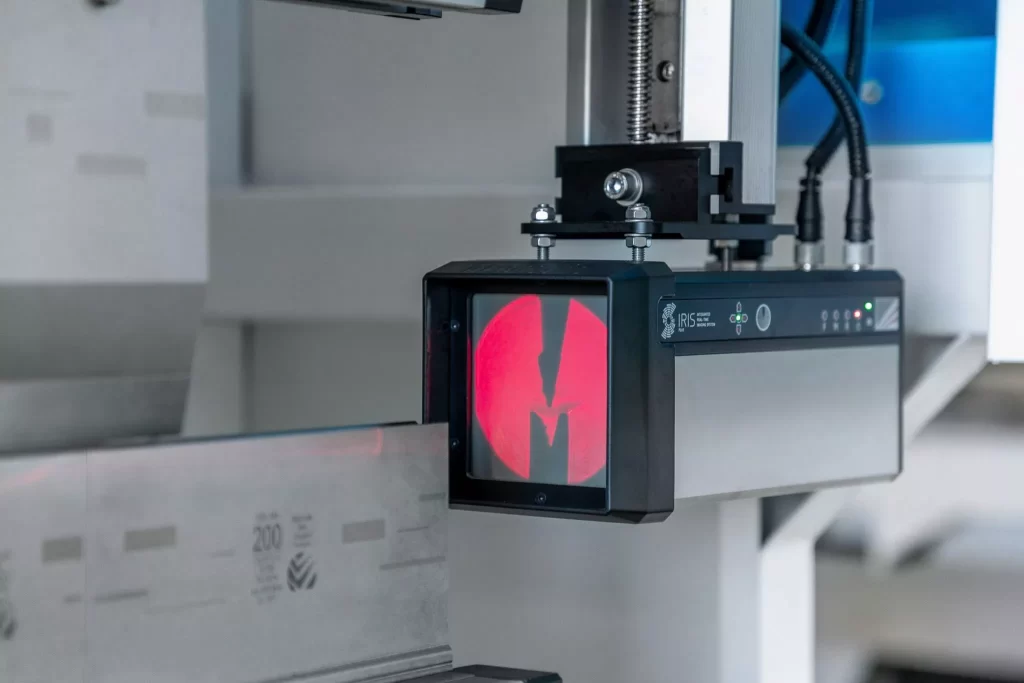

The LZS Series and IRIS Series Safety laser protection provide superior optical protection while maintaining the highest level of productivity and performance for CNC press brake.

CNC Control System

Over 35 Years Of Experience In Top Level Controls

Successfully controlling precision & productivity, modern sheet metal production is inconceivable without high performance software. Highly effective control algorithms optimize the machine cycle, reduce the time required for set-up and ensures consistently high quality.

TOP MIND is one of the world’s leading manufacturers in the field of steel metal working machinery for our Laser Cutting Systems & Press brakes.

Advantage:

- CLASS 1 Dual Block laser

- Fast response time

- Safety speed automatically monitored

- Stopping distance automatically monitored

- Status LEDs - Power / Front/middle/rear Sensors

- Tray mode for high speed bending of tray & box shapes

- Complex shapes can be achieved in high speed with Tray/Box Mode.

Automatic Tool Alignment:

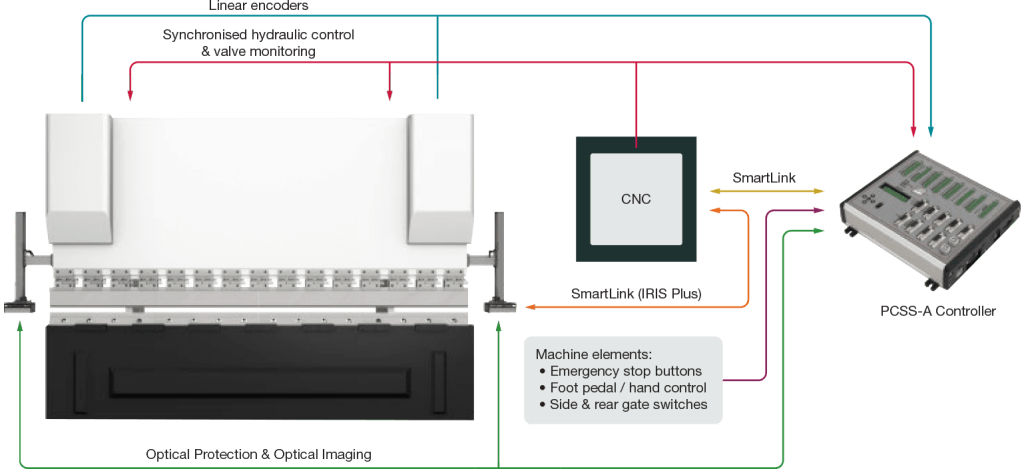

The systems with a camera receiver feature automatic tool alignment that eliminates the need for precise manual adjustment, and this process can also be fully automated in the CNC via SmartLink, eliminating the need for the operator to press the TOOL ALIGN button.

- CLASS 1 Dual Block laser

- Fast response time

- Safety speed automatically monitored

- Stopping distance automatically monitored

- Status LEDs - Power / Front/middle/rear Sensors

- Tray mode for high speed bending of tray & box shapes

- Complex shapes can be achieved in high speed with Tray/Box Mode.

Certification And Standards Compliance:

The OEM Embedded Systems LZS Series and IRIS Series hardware and software is CE Certified and compliant with all international press brake safety standards including EN12622, ANSI B11.3-2012, CSA Z142-10 and NR12.

Press Brake Control Safety System - Advanced

The PCSS-A is a programmable safety controller designed to improve the performance and safety of press brakes. It provides flexibility for the press brake manufacturer and simplifies the design process by combining all related control, safety and monitoring functions into a single system and eliminates the need for complex integration of third party components and software. PCSS-A provides an optimum balance of functionality and performance with reduced build cost.

This provides an efficient and cost effective platform with fewer components, reduced wiring, simplified interface and CE Certified hardware and software to minimise engineering and build time.

Specifications

| PCSS-A0 | PCSS-A0 PLUS | PCSS-A1 | PCSS-A2 |

|

| Technology | ||||

| SmartLink | • | • | • | • |

| FlexSpeed | • | • | • | Plus |

| AutoSense | Plus | Ultimate | Ultimate | Ultimate |

| Specifications | ||||

| Safety inputs | 12 | 12 | 16 | 16 |

| Safety outputs | 4 | 4 | 6 | 6 |

| Standard inputs | 24 | 24 | 28 | 28 |

| Standard outputs | 6 | 6 | 10 | 10 |

| Linear encoder I/O | 1, Y1 or Y2 | 2, both Y1 and Y2 | 2, both Y1 and Y2 | 2, both Y1 and Y2 |

| Minimum encoder resolution | 0.1 micron | 0.1 micron | 0.1 micron | 0.1 micron |

| Speed capacity of the encoder counters | >300mm per second | > 300mm per second | > 300mm per second | > 300mm per second |

| Response time (hardware interrupts) | <1ms | <1ms | <1ms | <1ms |

| SD Card (back-up, data logging and high-speed software transfer) | – | – | – | • |

| CAN Open | – | – | – | • |

| Ethernet | – | – | • | • |

| Ether CAT | – | – | – | OPTIONAL |

| Dimensions | 229mm x 189mm x 45mm | 229mm x 189mm x 45mm | 229mm x 189mm x 45mm | 229mm x 189mm x 57mm |

| Expansion Options |

||||

| Tandem Adaptor | – | – | • | • |

| SmartLink Brackets | – | – | • | • |

| Wireless Foot Pedal | – | – | • | • |

| Optics Compatibility |

||||

| LZS-1 |

• | • | • | • |

| LZS-2 |

• | • | • | • |

| LZS-XL | – | – | • | • |

| IRIS / IRIS Plus | – | – | • | • |

| Third party light curtain support |

• | • | • | • |

| Dual guarding support |

• | • | • | • |

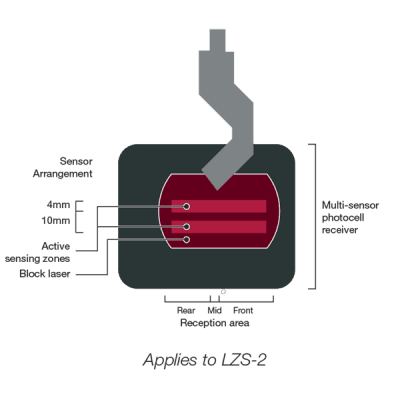

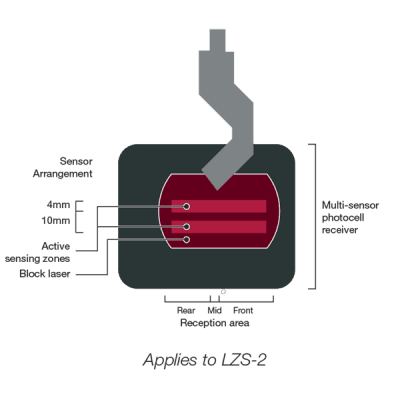

| LZS-1 | LZS-2 | LZS-XL | IRIS | IRIS PLUS |

|

| Optical protection functions |

• | • | • | • | • |

| Optical imaging functions | – | – | – | • | • |

| Laser transmitter | CLASS 1 | CLASS 1 | CLASS 1 | CLASS 1 | CLASS 1 |

| Receiver type | Multi-sensor photocell | Multi-sensor photocell | Camera | Camera with integrated Intel® image processor | Camera with integrated high-speed Intel® image processor |

| Maximum recommended optical range | 8 metres | 8 metres | 15 metres | 8 metres | 4.5 metres |

| Minimum object detection resolution | 4mm | 4mm | 9mm | 2mm | 2mm |

| Connector type | M12 8 pin | M12 8 pin | M12 12 pin | M12 12 pin | M12 12 pin |

| Tool compatibility | V tools and non-standard tools | V tools and non-standard tools | V tools and non-standard tools | V tools and non-standard tools | V tools and non-standard tools |

| Integrated status LEDs |

• | • | • | • | • |

| Special Functions |

|||||

| Automatic tool alignment | – | – | – | • | • |

| Automatic alignment confirmation | – | – | • | – | – |

| Special tools mode | – | – | – | • | • |

| Soft stop mode | – | – | – | • | • |

| Fast flattening mode | – | – | – | • | • |

| Automatic Cycle Start (ACS) | – | – | – | • | • |

| Bend Speed Management (BSM) | – | – | – | • | • |

| Adaptive Environment Sensing (AES) | – | – | • | • | • |

| Technology | |||||

| RapidBend | – | • | – | – | – |

| RapidBend Ultimate | – | – | – | • | • |

| BendShield | – | – | – | • | • |

| BendVision | – | – | – | – | • |

| Performance // Minimum speed change point |

|||||

| Flat sheet bending | 8mm | 4mm | 3mm / 10mm | 0mm | 0mm |

| Box bending | 8mm | 4mm | 3mm / 10mm | 0mm | 0mm |

| PCSS-A Series Compatibility |

|||||

| PCSS-A0 / PCSS-A0 Plus | • | • | – | – | – |

| PCSS-A1 / PCSS-A2 |

• | • | • | • | • |

| PCSS-A Tandem Adaptor | – | – | • | – | – |

| Mounting Bracket Compatibility |

|||||

| Economy Brackets | • | • | – | – | – |

| Standard Brackets |

• | • | • | • | • |

| SmartLink Brackets | – | – | – | • | • |

| IRIS | IRIS PLUS |

|

| Optical protection functions | • | • |

| Optical imaging functions | • | • |

| Maximum recommended optical range | 8 metres | 4.5 metres |

| Optical sensor | ||

| Camera | Digital Image Sensor | Digital Image Sensor |

| Frame rate / frequency | 17ms / 59Hz | Selectable 5ms / 200Hz or 10ms / 100Hz |

| Data resolution (sensor) | – | 0.01 degrees |

| Measurement technology | ||

| Type | Integrated Intel® image processor | Integrated high-speed Intel® image processor |

| Memory depth | – | Records up to 10 seconds (2000 images) of bend data per cycle |

| Measurement accuracy | – | Up to +/- 0.25 degrees |

| Measurement rate synchronised with frame rate | – | Selectable 5ms / 200Hz or 10ms / 100Hz |

| Imaging technology | ||

| Bend Speed Management | • | • |

| BendVision | – | • |

| ECONOMY | STANDARD | SMARTLINK | |

| Specifications | |||

| Vertical bracket length | 700mm | 520mm / 700mm / 1000mm | 700mm |

| Vertical adjustment range | 488mm | 350mm / 530mm / 830mm | 500mm |

| Horizontal adjustment range | 40mm | 40mm | 40mm |

| Maximum recommended machine length | 4 metres | 15 metres | 6 metres |

| Main Features | |||

| Precision linear bearings and rails | – | • | • |

| Free sliding operation | – | • | • |

| Automatic motorised drive system | – | – | • |

| Maximum speed of the motorised drive system | NA | NA | 20mm/s |

| Adjustable locking handle | • | • | NA |

| Tool change lock | – | Manual | Automatic |

| Optics Compatibility | |||

| LZS-1 | • | • | – |

| LZS-2 | • | • | – |

| LZS-XL | – | • | – |

| IRIS / IRIS Plus | – | • | • |