TOPMIND

Smart Torsion-Sync Press Brake 3~4 Axis

TOPMIND

Smart Torsion-Sync Press Brake 3~4 Axis

Smart Torsion-Sync CNC Press Brake for Sheet Metal Processing

Preferential Quality. Stability With A Competitive Price

WC67K series bending machine is equipped with standard single-axis backstop system (x-axis) and double-axis bending angle system (Y1,Y2-axis), optional addition of v-axis compensation function, and selection of appropriate molds, which can easily bend complex shaped workpiece.

Competitive Price

High Effeciency

Preferential Quality & Easy Operation

Standard 3+1 Axis,Y1Y2 Independent Control Flexibility

Standard Equipment

- CNC TP10S(STANDARD), E300P,DA41,CYBERTOUCH8 for choice.

- 10 inch TFT 256K touch screen

- The standard X,Y axis servo motor

- TOP MIND electric motorized crowning system

- USA SUNNY oil pump

- Optional machting support R, Z axis

- Taiwan YEOSHE hydraulic system

- High efficiency motor – HYEM Quiet Operation

- Electrical cabinet with Schneider electric system

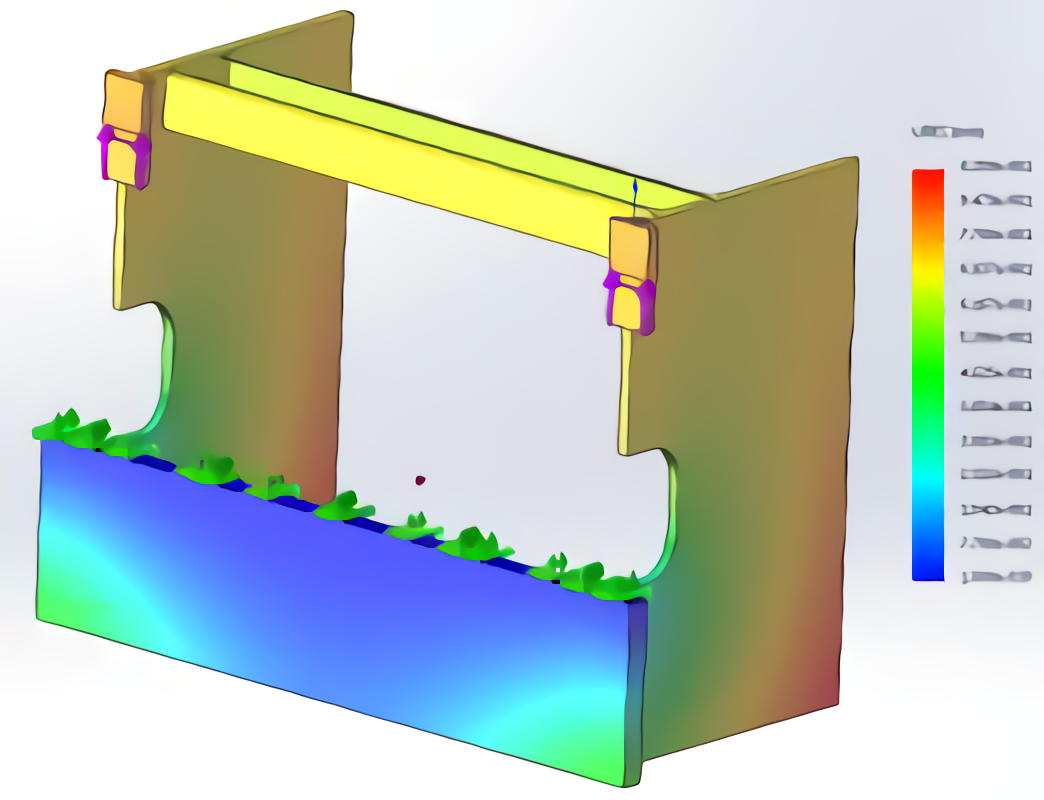

Intergral Processing&Finite Element Analysis

The integral processing ensures the overall precision of the machine tool.

The machine adopts double cylinder hydraulic drive to drive the slider down to complete the bending work. The first signal is given by TP10S-3+1 NUMERICAL control electrical system to control the opening and closing of the hydraulic valve, and the servo motor adjusts the stroke of the cylinder to drive the slider down quickly, which will change into the work speed when contacting the workpiece, and hold pressure for a period of time after the bending in place to achieve a fast return. By the torsion shaft and hydraulic synchronous device to ensure the synchronization of the double cylinder and effective anti-biased load capacity, the lowest position of the slide block down, by adjusting the oil cylinder retaining device control, and through the set time to achieve the return.

Frame Structure

Machine Body

TOP MIND about machine frame is made by welding left and right column with worktable, oil tank and bottom beam. After aging treatment, residual internal stress is eliminated to ensure sufficient stiffness and strength. After the completion of the machine assembly test machine, the machine is processed by the large floor boring and milling machine for the second time, so as to improve and ensure the high precision of the machine more effectively.

TP10S Touch CNC System(Standard)

- 10 Inch TFT 256K color touch screen

- The standard X,Y axis servo motor

- Support angle programming, automatically calculate the depth of plate bending

- Slider(Y axis) postion control

- Position control of rear stopper(X axis)

- 500 programs, each program 40 steps

- Soft limit function, power off memory

- Matching support R,Z axis

- Standard support for the degree of compensation

E300 Control System(Optional)

All Major Systems Available On The Market

- Support X, Y, R axis servo control, V axis mechanical compensation mode optional.

- Built-in machine control logic, hydraulic valve group logic free configuration

- Angle programming calculation function, built-in mold library and material table, improve the accuracy of Angle calculation

- Standard EDS/ProNet series servo, superior performance, stable quality

- Built-in parameter backup and one-click recovery function

- Micro switch button board, stable and reliable, long life

- Support one page programming, simple and clear, quick function key page selection, easy and quick operation

Crowning System

Deflection Compensation Device V Axis

Table oblique iron compensation device, CNC control, make the table to form a set of ideal convex curve, compensation slider and table deflection deformation, in order to obtain satisfactory deflection compensation, so that the folded workpiece in the length direction of the Angle is always consistent, improve the precision.

Stroke Adjusting Device For Rear Stopper & Slide Block

- The slider is an integral steel plate, which moves up and down along the guide rail under the action of two oil cylinders

- Slider is connected with the torsion bar to ensure the synchronization of left and right when the slide block goes down

- Servo motor is used to adjust the mechanical stopper and rear stopper

- Controlled by NUMERICAL control system, accurate display positioning and intuitive

- The rear stopper is installed on the left and right columns, with good rigidity and fast movement speed.

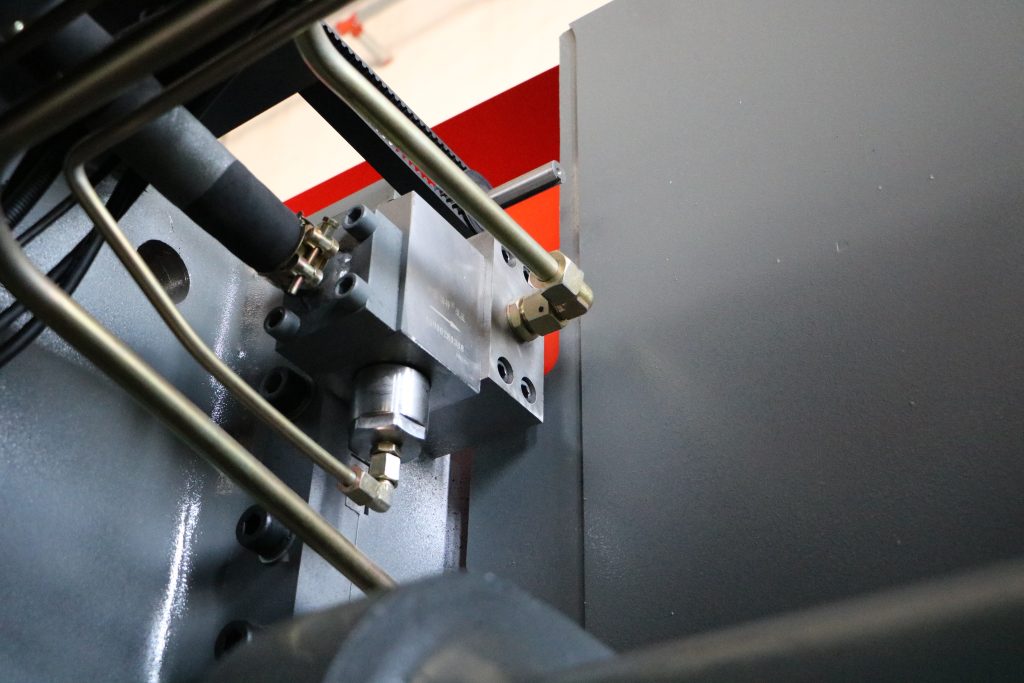

Oil Cylinder

Hydraulic cylinder and slider are the main moving parts of the bending machine, mainly composed of cylinder block, cylinder head, piston rod, nut, lead screw and so on. The oil cylinder adopts forgings with high strength, and all the dynamic seals adopt imported sealing rings, with stable performance, good sealing effect and long service life.

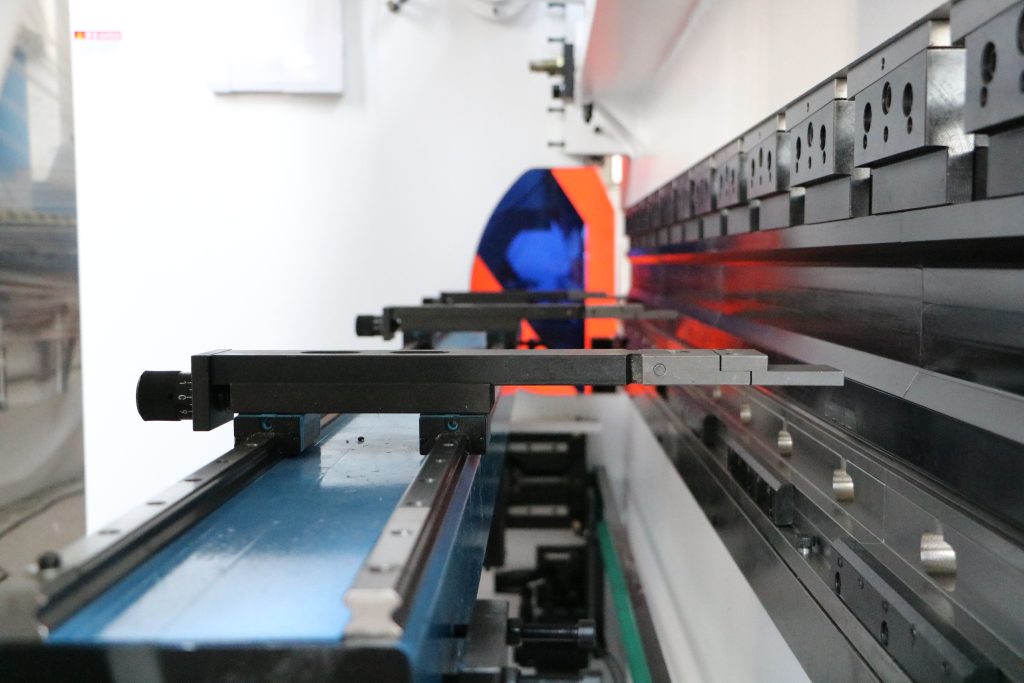

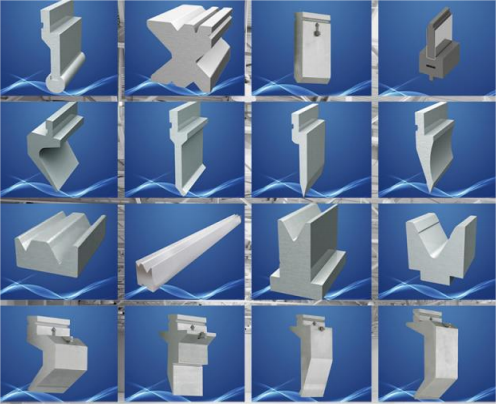

TOP MIND Toolings About Punch&Die

- The upper die is segmented, and the lower die is a special multi-V square nc die

- V-grooves of different widths are convenient for folding workpieces of different plate thickness

- Fast clamping mechanism for upper die has the characteristics of quick die changing, labor-saving and safe die changing

- Oblique iron deflection compensation function

- The amount of compensation can be adjusted according to different plate thickness, material and slot width

- Ensure the accuracy and straightness of each bending workpiece

Torsion Bar

Both ends of the torsion shaft are supported on the left and right columns and connected with the slide block to form a synchronous mechanism. With the unique hydraulic synchronous device, it greatly improves the anti-biased load capacity.

Hydraulic System

Taiwan YEOSHE Hydraulic System Reliable Brings High Value

TOPMIND promotes hydraulic integrated system, hydraulic oil pump group adopts internal high pressure gear pump, low noise, reliable operation.

Advantage:

- Twice heat treatment frame, high rigidity table, optional mechanical compensation device, precise bending.

- Hydraulic synchronous control ensures precise repeatability and ease of use.

- The integrated hydraulic system can quickly and automatically switch to slow corners.

- .X axis, Y1, Y2 axis are programmed by CNC TP10S system.(E300, DA41S for choice)

- Advanced variable frequency hydraulic control technology, more stable and reliable operation.

- The optinal parameter ratio and optinal core configuration ensure stable performance and easy operation.